UltraBorg - Precision servo control with ultrasonic module support

Main Examples

Download and installation instructions can be found on the getting started tab, as well as wiring instructions for the power, servo motors, and ultrasonic modules.The package of examples can be downloaded as a zip file directly: http://www.piborg.org/downloads/ultraborg/examples.zip

You can also view the code listings at the bottom of this page.

UltraBorg.py

This is the main library for UltraBorg, it simplifies operation from using I²C directly to simply calling simple named functions such asUB.SetServoPosition1(0.5)See the scripts below for examples of use, or the library function listings for usage guidance.

ubSequence.py

A simple script which controls the servos automatically based on an example sequence.This script demonstrates how simple operating UltraBorg can be ^_^

Lines 8 to 17 determine the sequence the rate each servo is moved at, as well as how far to move them.

Run using:

cd ~/ultraborg./ubSequence.pyubReadDistances.py

A simple script which reads the ultrasonic distances from all four modules.Note that this script checks the distances for a reading of

0.This is because the UltraBorg returns

0 if it either cannot see an ultrasonic module, or if the distance is out of range.This script uses the filtered ultrasonic readings.

Run using:

cd ~/ultraborg./ubReadDistances.pyubServoFromDistances.py

A slightly more advanced script which uses the distance readings to control the servo movement.Each servo is moved to a position based on how far away the corresponding distance reading is.

This example uses the unfiltered distance readings to get the fastest response to movement.

Lines 8 to 10 determine the distance range used to control the servos in mm.

Run using:

cd ~/ultraborg./ubServoFromDistances.pyubGui.py

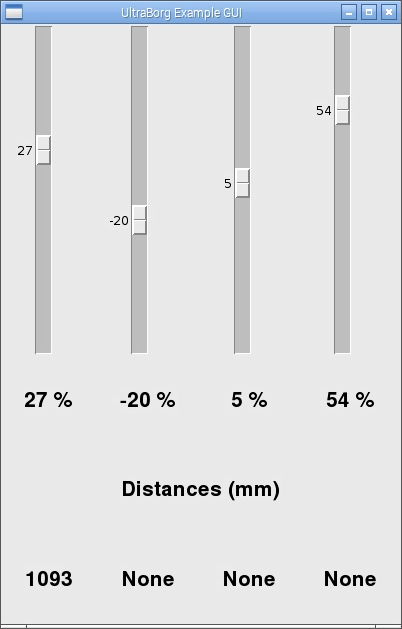

This script shows how you can make a GUI in Python which controls UltraBorg, as well as providing an easy to use interactive demonstration of the board.

Drag the sliders up and down to move the servos, the current positions are shown below the sliders.

The numbers at the bottom of the GUI are the filtered readings from the ultrasonic modules.

To get the same position as the GUI in a script divide the value shown by 100, e.g. if the GUI shows servo #1 as -35 and you want the same psoition run

UB.SetServoPosition1(-0.35) in your script.Run using:

cd ~/ultraborg./ubGui.pyor double-clicking the icon on the desktop.

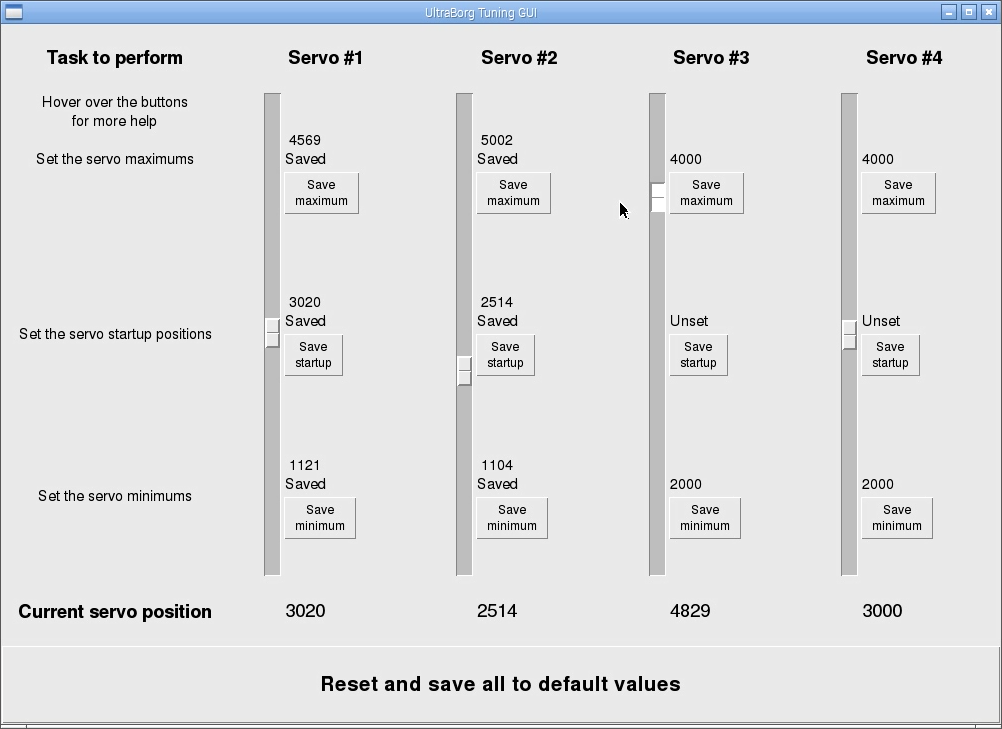

ubTuningGui.py

This is a complex script which we provide for tuning the servos to operate at full range.

The various buttons provide pop-up text to explain what they do.

See the UltraBorg servo tuning instructions for a more detailed description of how to use this GUI.

The GUI provides an example of how limits can be set from a script.

Run using:

cd ~/ultraborg./ubTuningGui.pyor double-clicking the icon on the desktop.

Arduino examples

UltraBorgArduino.ino

A simple sketch which controls the servos automatically based on an example sequence.It also reads the ultrasonic distances from all four modules when it starts and reports them via serial.

This script demonstrates how simple operating UltraBorg can be ^_^

Lines 53 to 61 determine the sequence the rate each servo is moved at, as well as how far to move them.

UltraBorgTuning.ino

This is a larger sketch which we provide for tuning the servos to operate at full range.The sketch uses the serial input / output to assist in finding and storing the limits of each servo.

See the UltraBorg Arduino servo tuning instructions for a more detailed description of how to use this example.

The sketch provides an example of how limits can be set from the Arduino, as well as how to set the raw PWM level if needed.

User Examples

Please post any examples you would like to share with others on the forum here.Library Functions

For Raspberry Pi use by creating an instance of the class, call the Init function, then command as desired, e.g.import UltraBorg UB = UltraBorg.UltraBorg() UB.Init() # User code here, use UB to control the boardFor Arduino pull in the header and call the UbInit function, then command as desired, e.g.

#include "UltraBorg.h"

...

if (!UbInit()) {

Serial.print("No UltraBorg!");

digitalWrite(13, HIGH);

}

// User code here, use Ub... to control the board

This call may be made either in the setup or loop functions.Multiple boards can be used when configured with different I²C addresses by creating multiple instances on the Raspberry Pi, e.g.

import UltraBorg UB1 = UltraBorg.UltraBorg() UB2 = UltraBorg.UltraBorg() UB1.i2cAddress = 0x44 UB2.i2cAddress = 0x45 UB1.Init() UB2.Init() # User code here, use UB1 and UB2 to control each board separatelyOn the Arduino the same can be done by changing the I²C address during the code, for example:

#include "UltraBorg.h"

...

Ubi2cAddress = 0x44

if (!UbInit()) {

Serial.print("No UltraBorg at 0x44!");

digitalWrite(13, HIGH);

}

Ubi2cAddress = 0x45

if (!UbInit()) {

Serial.print("No UltraBorg at 0x45!");

digitalWrite(13, HIGH);

}

// User code here, use Ub... to control the board, e.g.

Ubi2cAddress = 0x44

UbSetServoPosition1(0.0); // Set servo #1 on board at 0x44 to central

Ubi2cAddress = 0x45

UbSetServoPosition1(0.0); // Set servo #1 on board at 0x45 to central

Be careful if both boards have different servo limits, you may need to re-run UbInit() after changing the I²C address to get the correct servo limits for the board at that address.The rest of the calls are the same for Arduino as on the Raspberry Pi except for name.

Simply swap

UB. for Ub in the examples if you are using an Arduino.e.g.

UB.SetServoPosition1 on the Raspberry Pi becomesUbSetServoPosition1 on the Arduino.On a Raspberry Pi you can get explanations of the functions available by call the Help function, e.g.

import UltraBorg UB = UltraBorg.UltraBorg() UB.Help()The same help text is also found below.

In the below listing any function parameters surrounded by [ ] are optional and may be omitted.

Board Settings

These values should be accessed from a particular instance of the library, and may be set / read differently if more then one is created.Set these after creating an instance but before calling

Init(), for example to set the I²C address:import UltraBorg UB = UltraBorg.UltraBorg() UB.i2cAddress = 0x10 UB.Init()When reading these values to see if things have worked read after calling

Init(), for example to see if the board was found:

import UltraBorg

UB = UltraBorg.UltraBorg()

UB.Init()

if UB.foundChip:

print 'Yay !'

else:

print 'Aww...'

busNumber

I²C bus on which the UltraBorg is attached (Rev 1 is bus0, Rev 2 is bus 1), only applies to the Raspberry Pibus

The smbus object used to talk to the I²C bus, only use this to talk with other I²C devices, only applies to the Raspberry Pii2cAddress

The I²C address of the UltraBorg chip to controlfoundChip

True if the UltraBorg chip can be seen, False otherwise, on an Arduino check the return value from UbInit() insteadprintFunction

Function reference to call when printing text, ifNone "print" is used, only applies to the Raspberry PiBoard Functions

These represent the majority of the functionality of the UltraBorg, such as setting servo positions.Call these functions on an instance, after calling

Init(), e.g.import UltraBorg UB = UltraBorg.UltraBorg() UB.Init() UB.SetServoPosition1(0.4)

Print(message)

Wrapper used by the UltraBorg instance to print messages, will callprintFunction if set, print otherwiseNot applicable to Arduino

NoPrint(message)

Does nothing, intended for disabling diagnostic printout by using:UB = UltraBorg.UltraBorg()

UB.printFunction = UB.NoPrint

Not applicable to Arduino

Init([tryOtherBus])

Prepare the I2C driver for talking to the UltraBorgIf

tryOtherBus is True or omitted, this function will attempt to use the other bus if the UltraBorg devices can not be found on the current busNumbertryOtherBus is not applicable to Arduinovalue = GetWithRetry(function, count)

Attempts to read a value multiple times before giving upPass a get function with no parameters

e.g.

distance = GetWithRetry(UB.GetDistance1, 5)Will try

UB.GetDistance1() upto 5 times, returning when it gets a valueUseful for ensuring a read is successful

Not applicable to Arduino

worked = SetWithRetry(setFunction, getFunction, value, count)

Attempts to write a value multiple times before giving upPass a set function with one parameter, and a get function no parameters

The get function will be used to check if the set worked, if not it will be repeated

e.g.

worked = SetWithRetry(UB.SetServoMinimum1, UB.GetServoMinimum1, 2000, 5)Will try

UB.SetServoMinimum1(2000) upto 5 times, returning when UB.GetServoMinimum1 returns 2000.Useful for ensuring a write is successful

Not applicable to Arduino

i2cRecv = ReadWithCheck(address, command, length)

Attempts an I2C read, checks if the bus tried to read too fast and re-triesOnly intended for internal usage

Not applicable to Arduino

distance = GetDistance1()

Gets the filtered distance for ultrasonic module #1 in millimetersReturns

0 for no object detected or no ultrasonic module attachedIf you need a faster response try

GetRawDistance1 instead (no filtering)e.g.

0 → No object in range25 → Object 25 mm away1000 → Object 1000 mm (1 m) away3500 → Object 3500 mm (3.5 m) awaydistance = GetDistance2()

Gets the filtered distance for ultrasonic module #2 in millimetersReturns

0 for no object detected or no ultrasonic module attachedIf you need a faster response try

GetRawDistance2 instead (no filtering)e.g.

0 → No object in range25 → Object 25 mm away1000 → Object 1000 mm (1 m) away3500 → Object 3500 mm (3.5 m) awaydistance = GetDistance3()

Gets the filtered distance for ultrasonic module #3 in millimetersReturns

0 for no object detected or no ultrasonic module attachedIf you need a faster response try

GetRawDistance3 instead (no filtering)e.g.

0 → No object in range25 → Object 25 mm away1000 → Object 1000 mm (1 m) away3500 → Object 3500 mm (3.5 m) awaydistance = GetDistance4()

Gets the filtered distance for ultrasonic module #4 in millimetersReturns

0 for no object detected or no ultrasonic module attachedIf you need a faster response try

GetRawDistance4 instead (no filtering)e.g.

0 → No object in range25 → Object 25 mm away1000 → Object 1000 mm (1 m) away3500 → Object 3500 mm (3.5 m) awaydistance = GetRawDistance1()

Gets the raw distance for ultrasonic module #1 in millimetersReturns

0 for no object detected or no ultrasonic module attachedFor a filtered (less jumpy) reading use

GetDistance1e.g.

0 → No object in range25 → Object 25 mm away1000 → Object 1000 mm (1 m) away3500 → Object 3500 mm (3.5 m) awaydistance = GetRawDistance2()

Gets the raw distance for ultrasonic module #2 in millimetersReturns

0 for no object detected or no ultrasonic module attachedFor a filtered (less jumpy) reading use

GetDistance2e.g.

0 → No object in range25 → Object 25 mm away1000 → Object 1000 mm (1 m) away3500 → Object 3500 mm (3.5 m) awaydistance = GetRawDistance3()

Gets the raw distance for ultrasonic module #3 in millimetersReturns

0 for no object detected or no ultrasonic module attachedFor a filtered (less jumpy) reading use

GetDistance3e.g.

0 → No object in range25 → Object 25 mm away1000 → Object 1000 mm (1 m) away3500 → Object 3500 mm (3.5 m) awaydistance = GetRawDistance4()

Gets the distance for ultrasonic module #4 in millimetersReturns

0 for no object detected or no ultrasonic module attachedFor a filtered (less jumpy) reading use

GetDistance4e.g.

0 → No object in range25 → Object 25 mm away1000 → Object 1000 mm (1 m) away3500 → Object 3500 mm (3.5 m) awayposition = GetServoPosition1()

Gets the drive position for servo output #10 is central, -1 is maximum left, +1 is maximum right

e.g.

0 → Central0.5 → 50% to the right1 → 100% to the right-0.75 → 75% to the leftposition = GetServoPosition2()

Gets the drive position for servo output #20 is central, -1 is maximum left, +1 is maximum right

e.g.

0 → Central0.5 → 50% to the right1 → 100% to the right-0.75 → 75% to the leftposition = GetServoPosition3()

Gets the drive position for servo output #30 is central, -1 is maximum left, +1 is maximum right

e.g.

0 → Central0.5 → 50% to the right1 → 100% to the right-0.75 → 75% to the leftposition = GetServoPosition4()

Gets the drive position for servo output #40 is central, -1 is maximum left, +1 is maximum right

e.g.

0 → Central0.5 → 50% to the right1 → 100% to the right-0.75 → 75% to the leftSetServoPosition1(position)

Sets the drive position for servo output #10 is central, -1 is maximum left, +1 is maximum right

e.g.

0 → Central0.5 → 50% to the right1 → 100% to the right-0.75 → 75% to the leftSetServoPosition2(position)

Sets the drive position for servo output #20 is central, -1 is maximum left, +1 is maximum right

e.g.

0 → Central0.5 → 50% to the right1 → 100% to the right-0.75 → 75% to the leftSetServoPosition3(position)

Sets the drive position for servo output #30 is central, -1 is maximum left, +1 is maximum right

e.g.

0 → Central0.5 → 50% to the right1 → 100% to the right-0.75 → 75% to the leftSetServoPosition4(position)

Sets the drive position for servo output #40 is central, -1 is maximum left, +1 is maximum right

e.g.

0 → Central0.5 → 50% to the right1 → 100% to the right-0.75 → 75% to the leftpwmLevel = GetServoMinimum1()

Gets the minimum PWM level for servo output #1This corresponds to position -1

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 → 1 ms servo burst, typical shortest burst4000 → 2 ms servo burst, typical longest burst3000 → 1.5 ms servo burst, typical centre5000 → 2.5 ms servo burst, higher than typical longest burst pwmLevel = GetServoMinimum2()

Gets the minimum PWM level for servo output #2This corresponds to position -1

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 → 1 ms servo burst, typical shortest burst4000 → 2 ms servo burst, typical longest burst3000 → 1.5 ms servo burst, typical centre5000 → 2.5 ms servo burst, higher than typical longest burst pwmLevel = GetServoMinimum3()

Gets the minimum PWM level for servo output #3This corresponds to position -1

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 → 1 ms servo burst, typical shortest burst4000 → 2 ms servo burst, typical longest burst3000 → 1.5 ms servo burst, typical centre5000 → 2.5 ms servo burst, higher than typical longest burst pwmLevel = GetServoMinimum4()

Gets the minimum PWM level for servo output #4This corresponds to position -1

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 → 1 ms servo burst, typical shortest burst4000 → 2 ms servo burst, typical longest burst3000 → 1.5 ms servo burst, typical centre5000 → 2.5 ms servo burst, higher than typical longest burst pwmLevel = GetServoMaximum1()

Gets the maximum PWM level for servo output #1This corresponds to position +1

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 → 1 ms servo burst, typical shortest burst4000 → 2 ms servo burst, typical longest burst3000 → 1.5 ms servo burst, typical centre5000 → 2.5 ms servo burst, higher than typical longest burst pwmLevel = GetServoMaximum2()

Gets the maximum PWM level for servo output #2This corresponds to position +1

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 → 1 ms servo burst, typical shortest burst4000 → 2 ms servo burst, typical longest burst3000 → 1.5 ms servo burst, typical centre5000 → 2.5 ms servo burst, higher than typical longest burst pwmLevel = GetServoMaximum3()

Gets the maximum PWM level for servo output #3This corresponds to position +1

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 → 1 ms servo burst, typical shortest burst4000 → 2 ms servo burst, typical longest burst3000 → 1.5 ms servo burst, typical centre5000 → 2.5 ms servo burst, higher than typical longest burst pwmLevel = GetServoMaximum4()

Gets the maximum PWM level for servo output #4This corresponds to position +1

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 → 1 ms servo burst, typical shortest burst4000 → 2 ms servo burst, typical longest burst3000 → 1.5 ms servo burst, typical centre5000 → 2.5 ms servo burst, higher than typical longest burst pwmLevel = GetServoStartup1()

Gets the startup PWM level for servo output #1This can be anywhere in the minimum to maximum range

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 → 1 ms servo burst, typical shortest burst4000 → 2 ms servo burst, typical longest burst3000 → 1.5 ms servo burst, typical centre5000 → 2.5 ms servo burst, higher than typical longest burst pwmLevel = GetServoStartup2()

Gets the startup PWM level for servo output #2This can be anywhere in the minimum to maximum range

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 → 1 ms servo burst, typical shortest burst4000 → 2 ms servo burst, typical longest burst3000 → 1.5 ms servo burst, typical centre5000 → 2.5 ms servo burst, higher than typical longest burst pwmLevel = GetServoStartup3()

Gets the startup PWM level for servo output #3This can be anywhere in the minimum to maximum range

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 → 1 ms servo burst, typical shortest burst4000 → 2 ms servo burst, typical longest burst3000 → 1.5 ms servo burst, typical centre5000 → 2.5 ms servo burst, higher than typical longest burst pwmLevel = GetServoStartup4()

Gets the startup PWM level for servo output #4This can be anywhere in the minimum to maximum range

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 → 1 ms servo burst, typical shortest burst4000 → 2 ms servo burst, typical longest burst3000 → 1.5 ms servo burst, typical centre, 5000 → 2.5 ms servo burst, higher than typical longest burst CalibrateServoPosition1(pwmLevel)

Sets the raw PWM level for servo output #1This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

Setting values outside the range of the servo for extended periods of time can damage the servo

NO LIMIT CHECKING IS PERFORMED BY THIS COMMAND!

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition1 / The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleCalibrateServoPosition2(pwmLevel)

Sets the raw PWM level for servo output #2This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

Setting values outside the range of the servo for extended periods of time can damage the servo

NO LIMIT CHECKING IS PERFORMED BY THIS COMMAND!

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition2 / The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleCalibrateServoPosition3(pwmLevel)

Sets the raw PWM level for servo output #3This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

Setting values outside the range of the servo for extended periods of time can damage the servo

NO LIMIT CHECKING IS PERFORMED BY THIS COMMAND!

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition3 / GetServoPosition3The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleCalibrateServoPosition4(pwmLevel)

Sets the raw PWM level for servo output #4This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

Setting values outside the range of the servo for extended periods of time can damage the servo

NO LIMIT CHECKING IS PERFORMED BY THIS COMMAND!

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition4 / GetServoPosition4The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cyclepwmLevel = GetRawServoPosition1()

Gets the raw PWM level for servo output #1This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

This value requires interpreting into an actual servo position, this is already done by

GetServoPosition1We recommend using the tuning GUI for setting the servo limits for

SetServoPosition1 / GetServoPosition1The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cyclepwmLevel = GetRawServoPosition2()

Gets the raw PWM level for servo output #2This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

This value requires interpreting into an actual servo position, this is already done by

GetServoPosition2We recommend using the tuning GUI for setting the servo limits for

SetServoPosition2 / GetServoPosition2The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cyclepwmLevel = GetRawServoPosition3()

Gets the raw PWM level for servo output #3This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

This value requires interpreting into an actual servo position, this is already done by

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition3 / GetServoPosition3The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cyclepwmLevel = GetRawServoPosition4()

Gets the raw PWM level for servo output #4This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

This value requires interpreting into an actual servo position, this is already done by

GetServoPosition4We recommend using the tuning GUI for setting the servo limits for

SetServoPosition4 / GetServoPosition4The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleSetServoMinimum1(pwmLevel)

Sets the minimum PWM level for servo output #1This corresponds to position -1

This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

Setting values outside the range of the servo for extended periods of time can damage the servo

LIMIT CHECKING IS ALTERED BY THIS COMMAND!

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition1 / GetServoPosition1The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleSetServoMinimum2(pwmLevel)

Sets the minimum PWM level for servo output #2This corresponds to position -1

This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

Setting values outside the range of the servo for extended periods of time can damage the servo

LIMIT CHECKING IS ALTERED BY THIS COMMAND!

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition2 / GetServoPosition2The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleSetServoMinimum3(pwmLevel)

Sets the minimum PWM level for servo output #3This corresponds to position -1

This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

Setting values outside the range of the servo for extended periods of time can damage the servo

LIMIT CHECKING IS ALTERED BY THIS COMMAND!

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition3 / GetServoPosition3The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleSetServoMinimum4(pwmLevel)

Sets the minimum PWM level for servo output #4This corresponds to position -1

This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

Setting values outside the range of the servo for extended periods of time can damage the servo

LIMIT CHECKING IS ALTERED BY THIS COMMAND!

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition4 / GetServoPosition4The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleSetServoMaximum1(pwmLevel)

Sets the maximum PWM level for servo output #1This corresponds to position +1

This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

Setting values outside the range of the servo for extended periods of time can damage the servo

LIMIT CHECKING IS ALTERED BY THIS COMMAND!

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition1 / GetServoPosition1The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleSetServoMaximum2(pwmLevel)

Sets the maximum PWM level for servo output #2This corresponds to position +1

This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

Setting values outside the range of the servo for extended periods of time can damage the servo

LIMIT CHECKING IS ALTERED BY THIS COMMAND!

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition2 / GetServoPosition2The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleSetServoMaximum3(pwmLevel)

Sets the maximum PWM level for servo output #3This corresponds to position +1

This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

Setting values outside the range of the servo for extended periods of time can damage the servo

LIMIT CHECKING IS ALTERED BY THIS COMMAND!

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition3 / GetServoPosition3The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleSetServoMaximum4(pwmLevel)

Sets the maximum PWM level for servo output #4This corresponds to position +1

This value can be set anywhere from 0 for a 0% duty cycle to 65535 for a 100% duty cycle

Setting values outside the range of the servo for extended periods of time can damage the servo

LIMIT CHECKING IS ALTERED BY THIS COMMAND!

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition4 / GetServoPosition4The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleSetServoStartup1(pwmLevel)

Sets the startup PWM level for servo output #1This can be anywhere in the minimum to maximum range

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition1 / GetServoPosition1This value is checked against the current servo limits before setting

The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleSetServoStartup2(pwmLevel)

Sets the startup PWM level for servo output #2This can be anywhere in the minimum to maximum range

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition2 / GetServoPosition2This value is checked against the current servo limits before setting

The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleSetServoStartup3(pwmLevel)

Sets the startup PWM level for servo output #3This can be anywhere in the minimum to maximum range

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition3 / GetServoPosition3This value is checked against the current servo limits before setting

The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleSetServoStartup4(pwmLevel)

Sets the startup PWM level for servo output #4This can be anywhere in the minimum to maximum range

We recommend using the tuning GUI for setting the servo limits for

SetServoPosition4 / GetServoPosition4This value is checked against the current servo limits before setting

The value is an integer where 2000 represents a 1ms servo burst, approximately 3% duty cycle

e.g.

2000 → 1 ms servo burst, typical shortest burst, ~3% duty cycle4000 → 2 ms servo burst, typical longest burst, ~ 6.1% duty cycle3000 → 1.5 ms servo burst, typical centre, ~4.6% duty cycle5000 → 2.5 ms servo burst, higher than typical longest burst, ~ 7.6% duty cycleHelp()

Displays the names and descriptions of the various functions and settings providedNot applicable to Arduino

Code Listings

ubSequence.py

#!/usr/bin/env python

# coding: latin-1

# Import the libraries we need

import UltraBorg

import time

# Settings

servoMin = -1.0 # Smallest servo position to use

servoMax = +1.0 # Largest servo position to use

startupDelay = 0.5 # Delay before making the initial move

stepDelay = 0.1 # Delay between steps

rateStart = 0.05 # Step distance for all servos during initial move

rateServo1 = 0.01 # Step distance for servo #1

rateServo2 = 0.02 # Step distance for servo #2

rateServo3 = 0.04 # Step distance for servo #3

rateServo4 = 0.08 # Step distance for servo #4

# Start the UltraBorg

UB = UltraBorg.UltraBorg() # Create a new UltraBorg object

UB.Init() # Set the board up (checks the board is connected)

# Loop over the sequence until the user presses CTRL+C

print 'Press CTRL+C to finish'

try:

print 'Move to central'

# Initial settings

servo1 = 0.0

servo2 = 0.0

servo3 = 0.0

servo4 = 0.0

# Set our initial servo positions

UB.SetServoPosition1(servo1)

UB.SetServoPosition2(servo2)

UB.SetServoPosition3(servo3)

UB.SetServoPosition4(servo4)

# Wait a while to be sure the servos have caught up

time.sleep(startupDelay)

print 'Sweep to start position'

while servo1 > servoMin:

# Reduce the servo positions

servo1 -= rateStart

servo2 -= rateStart

servo3 -= rateStart

servo4 -= rateStart

# Check if they are too small

if servo1 < servoMin:

servo1 = servoMin

servo2 = servoMin

servo3 = servoMin

servo4 = servoMin

# Set our new servo positions

UB.SetServoPosition1(servo1)

UB.SetServoPosition2(servo2)

UB.SetServoPosition3(servo3)

UB.SetServoPosition4(servo4)

# Wait until the next step

time.sleep(stepDelay)

print 'Sweep all servos through the range'

while True:

# Increase the servo positions at separate rates

servo1 += rateServo1

servo2 += rateServo2

servo3 += rateServo3

servo4 += rateServo4

# Check if any of them are too large, if so wrap to the over end

if servo1 > servoMax:

servo1 -= (servoMax - servoMin)

if servo2 > servoMax:

servo2 -= (servoMax - servoMin)

if servo3 > servoMax:

servo3 -= (servoMax - servoMin)

if servo4 > servoMax:

servo4 -= (servoMax - servoMin)

# Set our new servo positions

UB.SetServoPosition1(servo1)

UB.SetServoPosition2(servo2)

UB.SetServoPosition3(servo3)

UB.SetServoPosition4(servo4)

# Wait until the next step

time.sleep(stepDelay)

except KeyboardInterrupt:

# User has pressed CTRL+C

print 'Done'

ubReadDistances.py

#!/usr/bin/env python

# coding: latin-1

# Import the libraries we need

import UltraBorg

import time

# Start the UltraBorg

UB = UltraBorg.UltraBorg() # Create a new UltraBorg object

UB.Init() # Set the board up (checks the board is connected)

# Loop over the sequence until the user presses CTRL+C

print 'Press CTRL+C to finish'

try:

while True:

# Read all four ultrasonic values

usm1 = UB.GetDistance1()

usm2 = UB.GetDistance2()

usm3 = UB.GetDistance3()

usm4 = UB.GetDistance4()

# Convert to the nearest millimeter

usm1 = int(usm1)

usm2 = int(usm2)

usm3 = int(usm3)

usm4 = int(usm4)

# Display the readings

if usm1 == 0:

print '#1 No reading'

else:

print '#1 % 4d mm' % (usm1)

if usm2 == 0:

print '#2 No reading'

else:

print '#2 % 4d mm' % (usm2)

if usm3 == 0:

print '#3 No reading'

else:

print '#3 % 4d mm' % (usm3)

if usm4 == 0:

print '#4 No reading'

else:

print '#4 % 4d mm' % (usm4)

print

# Wait between readings

time.sleep(.1)

except KeyboardInterrupt:

# User has pressed CTRL+C

print 'Done'

ubServoFromDistances.py

#!/usr/bin/env python

# coding: latin-1

# Import the libraries we need

import UltraBorg

import time

# Settings

distanceMin = 100.0 # Minimum distance in mm, corresponds to servo at -100%

distanceMax = 300.0 # Maximum distance in mm, corresponds to servo at +100%

# Start the UltraBorg

UB = UltraBorg.UltraBorg() # Create a new UltraBorg object

UB.Init() # Set the board up (checks the board is connected)

# Calculate our divisor

distanceDiv = (distanceMax - distanceMin) / 2.0

# Loop over the sequence until the user presses CTRL+C

print 'Press CTRL+C to finish'

try:

# Initial settings

servo1 = 0.0

servo2 = 0.0

servo3 = 0.0

servo4 = 0.0

while True:

# Read all four ultrasonic values, we use the raw values so we respond quickly

usm1 = UB.GetRawDistance1()

usm2 = UB.GetRawDistance2()

usm3 = UB.GetRawDistance3()

usm4 = UB.GetRawDistance4()

# Convert to the nearest millimeter

usm1 = int(usm1)

usm2 = int(usm2)

usm3 = int(usm3)

usm4 = int(usm4)

# Generate the servo positions based on the distance readings

if usm1 != 0:

servo1 = ((usm1 - distanceMin) / distanceDiv) - 1.0

if servo1 > 1.0:

servo1 = 1.0

elif servo1 < -1.0:

servo1 = -1.0

if usm2 != 0:

servo2 = ((usm2 - distanceMin) / distanceDiv) - 1.0

if servo2 > 1.0:

servo2 = 1.0

elif servo2 < -1.0:

servo2 = -1.0

if usm3 != 0:

servo3 = ((usm3 - distanceMin) / distanceDiv) - 1.0

if servo3 > 1.0:

servo3 = 1.0

elif servo3 < -1.0:

servo3 = -1.0

if usm4 != 0:

servo4 = ((usm4 - distanceMin) / distanceDiv) - 1.0

if servo4 > 1.0:

servo4 = 1.0

elif servo4 < -1.0:

servo4 = -1.0

# Display our readings

print '%4d mm -> %.1f %%' % (usm1, servo1 * 100.0)

print '%4d mm -> %.1f %%' % (usm2, servo2 * 100.0)

print '%4d mm -> %.1f %%' % (usm3, servo3 * 100.0)

print '%4d mm -> %.1f %%' % (usm4, servo4 * 100.0)

print

# Set our new servo positions

UB.SetServoPosition1(servo1)

UB.SetServoPosition2(servo2)

UB.SetServoPosition3(servo3)

UB.SetServoPosition4(servo4)

# Wait between readings

time.sleep(.1)

except KeyboardInterrupt:

# User has pressed CTRL+C

print 'Done'

ubGui.py

#!/usr/bin/env python

# coding: latin-1

# Import library functions we need

import UltraBorg

import Tkinter

# Start the UltraBorg

global UB

UB = UltraBorg.UltraBorg() # Create a new UltraBorg object

UB.Init() # Set the board up (checks the board is connected)

# Class representing the GUI dialog

class UltraBorg_tk(Tkinter.Tk):

# Constructor (called when the object is first created)

def __init__(self, parent):

Tkinter.Tk.__init__(self, parent)

self.parent = parent

self.protocol("WM_DELETE_WINDOW", self.OnExit) # Call the OnExit function when user closes the dialog

self.Initialise()

# Initialise the dialog

def Initialise(self):

global UB

self.title('UltraBorg Example GUI')

# Setup a grid of 4 sliders which command each servo output, plus 4 readings for the servo positions and distances

self.grid()

# The servo sliders

self.sld1 = Tkinter.Scale(self, from_ = +100, to = -100, orient = Tkinter.VERTICAL, command = self.sld1_move)

self.sld1.set(0)

self.sld1.grid(column = 0, row = 0, rowspan = 1, columnspan = 1, sticky = 'NSEW')

self.sld2 = Tkinter.Scale(self, from_ = +100, to = -100, orient = Tkinter.VERTICAL, command = self.sld2_move)

self.sld2.set(0)

self.sld2.grid(column = 1, row = 0, rowspan = 1, columnspan = 1, sticky = 'NSEW')

self.sld3 = Tkinter.Scale(self, from_ = +100, to = -100, orient = Tkinter.VERTICAL, command = self.sld3_move)

self.sld3.set(0)

self.sld3.grid(column = 2, row = 0, rowspan = 1, columnspan = 1, sticky = 'NSEW')

self.sld4 = Tkinter.Scale(self, from_ = +100, to = -100, orient = Tkinter.VERTICAL, command = self.sld4_move)

self.sld4.set(0)

self.sld4.grid(column = 3, row = 0, rowspan = 1, columnspan = 1, sticky = 'NSEW')

# The servo values (read from the controller)

self.lblServo1 = Tkinter.Label(self, text = '-')

self.lblServo1['font'] = ('Arial', 20, 'bold')

self.lblServo1.grid(column = 0, row = 1, columnspan = 1, rowspan = 1, sticky = 'NSEW')

self.lblServo2 = Tkinter.Label(self, text = '-')

self.lblServo2['font'] = ('Arial', 20, 'bold')

self.lblServo2.grid(column = 1, row = 1, columnspan = 1, rowspan = 1, sticky = 'NSEW')

self.lblServo3 = Tkinter.Label(self, text = '-')

self.lblServo3['font'] = ('Arial', 20, 'bold')

self.lblServo3.grid(column = 2, row = 1, columnspan = 1, rowspan = 1, sticky = 'NSEW')

self.lblServo4 = Tkinter.Label(self, text = '-')

self.lblServo4['font'] = ('Arial', 20, 'bold')

self.lblServo4.grid(column = 3, row = 1, columnspan = 1, rowspan = 1, sticky = 'NSEW')

# The distance readings and a heading

self.lblDistanceHeading = Tkinter.Label(self, text = 'Distances (mm)')

self.lblDistanceHeading['font'] = ('Arial', 20, 'bold')

self.lblDistanceHeading.grid(column = 0, row = 2, columnspan = 4, rowspan = 1, sticky = 'NSEW')

self.lblDistance1 = Tkinter.Label(self, text = '-')

self.lblDistance1['font'] = ('Arial', 20, 'bold')

self.lblDistance1.grid(column = 0, row = 3, columnspan = 1, rowspan = 1, sticky = 'NSEW')

self.lblDistance2 = Tkinter.Label(self, text = '-')

self.lblDistance2['font'] = ('Arial', 20, 'bold')

self.lblDistance2.grid(column = 1, row = 3, columnspan = 1, rowspan = 1, sticky = 'NSEW')

self.lblDistance3 = Tkinter.Label(self, text = '-')

self.lblDistance3['font'] = ('Arial', 20, 'bold')

self.lblDistance3.grid(column = 2, row = 3, columnspan = 1, rowspan = 1, sticky = 'NSEW')

self.lblDistance4 = Tkinter.Label(self, text = '-')

self.lblDistance4['font'] = ('Arial', 20, 'bold')

self.lblDistance4.grid(column = 3, row = 3, columnspan = 1, rowspan = 1, sticky = 'NSEW')

# The grid sizing

self.grid_columnconfigure(0, weight = 1)

self.grid_columnconfigure(1, weight = 1)

self.grid_columnconfigure(2, weight = 1)

self.grid_columnconfigure(3, weight = 1)

self.grid_rowconfigure(0, weight = 4)

self.grid_rowconfigure(1, weight = 1)

self.grid_rowconfigure(2, weight = 1)

self.grid_rowconfigure(3, weight = 1)

# Set the size of the dialog

self.resizable(True, True)

self.geometry('400x600')

# Start polling for readings

self.poll()

# Polling function

def poll(self):

global UB

# Read the servo positions

servo1 = UB.GetServoPosition1()

servo2 = UB.GetServoPosition2()

servo3 = UB.GetServoPosition3()

servo4 = UB.GetServoPosition4()

# Read the ultrasonic distances

distance1 = int(UB.GetDistance1())

distance2 = int(UB.GetDistance2())

distance3 = int(UB.GetDistance3())

distance4 = int(UB.GetDistance4())

# Set the servo displays

self.lblServo1['text'] = '%.0f %%' % (servo1 * 100.0)

self.lblServo2['text'] = '%.0f %%' % (servo2 * 100.0)

self.lblServo3['text'] = '%.0f %%' % (servo3 * 100.0)

self.lblServo4['text'] = '%.0f %%' % (servo4 * 100.0)

# Set the ultrasonic displays

if distance1 == 0:

self.lblDistance1['text'] = 'None'

else:

self.lblDistance1['text'] = '%4d' % (distance1)

if distance2 == 0:

self.lblDistance2['text'] = 'None'

else:

self.lblDistance2['text'] = '%4d' % (distance2)

if distance3 == 0:

self.lblDistance3['text'] = 'None'

else:

self.lblDistance3['text'] = '%4d' % (distance3)

if distance4 == 0:

self.lblDistance4['text'] = 'None'

else:

self.lblDistance4['text'] = '%4d' % (distance4)

# Prime the next poll

self.after(200, self.poll)

# Called when the user closes the dialog

def OnExit(self):

# End the program

self.quit()

# Called when sld1 is moved

def sld1_move(self, value):

global UB

UB.SetServoPosition1(float(value) / 100.0)

# Called when sld2 is moved

def sld2_move(self, value):

global UB

UB.SetServoPosition2(float(value) / 100.0)

# Called when sld3 is moved

def sld3_move(self, value):

global UB

UB.SetServoPosition3(float(value) / 100.0)

# Called when sld4 is moved

def sld4_move(self, value):

global UB

UB.SetServoPosition4(float(value) / 100.0)

# if we are the main program (python was passed a script) load the dialog automatically

if __name__ == "__main__":

app = UltraBorg_tk(None)

app.mainloop()

UltraBorg.py

#!/usr/bin/env python

# coding: latin-1

"""

This module is designed to communicate with the UltraBorg

Use by creating an instance of the class, call the Init function, then command as desired, e.g.

import UltraBorg

UB = UltraBorg.UltraBorg()

UB.Init()

# User code here, use UB to control the board

Multiple boards can be used when configured with different I²C addresses by creating multiple instances, e.g.

import UltraBorg

UB1 = UltraBorg.UltraBorg()

UB2 = UltraBorg.UltraBorg()

UB1.i2cAddress = 0x44

UB2.i2cAddress = 0x45

UB1.Init()

UB2.Init()

# User code here, use UB1 and UB2 to control each board separately

For explanations of the functions available call the Help function, e.g.

import UltraBorg

UB = UltraBorg.UltraBorg()

UB.Help()

See the website at www.piborg.org/ultraborg for more details

"""

# Import the libraries we need

import smbus

import types

import time

# Constant values

I2C_MAX_LEN = 4

USM_US_TO_MM = 0.171500

PWM_MIN = 2000 # Should be a 1 ms burst, typical servo minimum

PWM_MAX = 4000 # Should be a 2 ms burst, typical servo maximum

DELAY_AFTER_EEPROM = 0.01 # Time to wait after updating an EEPROM value before reading

PWM_UNSET = 0xFFFF

READ_TOO_FAST = 0xED # We seem to get this for the first byte sometimes on the RPi v2

I2C_ID_SERVO_USM = 0x36

COMMAND_GET_TIME_USM1 = 1 # Get the time measured by ultrasonic #1 in us (0 for no detection)

COMMAND_GET_TIME_USM2 = 2 # Get the time measured by ultrasonic #2 in us (0 for no detection)

COMMAND_GET_TIME_USM3 = 3 # Get the time measured by ultrasonic #3 in us (0 for no detection)

COMMAND_GET_TIME_USM4 = 4 # Get the time measured by ultrasonic #4 in us (0 for no detection)

COMMAND_SET_PWM1 = 5 # Set the PWM duty cycle for drive #1 (16 bit)

COMMAND_GET_PWM1 = 6 # Get the PWM duty cycle for drive #1 (16 bit)

COMMAND_SET_PWM2 = 7 # Set the PWM duty cycle for drive #2 (16 bit)

COMMAND_GET_PWM2 = 8 # Get the PWM duty cycle for drive #2 (16 bit)

COMMAND_SET_PWM3 = 9 # Set the PWM duty cycle for drive #3 (16 bit)

COMMAND_GET_PWM3 = 10 # Get the PWM duty cycle for drive #3 (16 bit)

COMMAND_SET_PWM4 = 11 # Set the PWM duty cycle for drive #4 (16 bit)

COMMAND_GET_PWM4 = 12 # Get the PWM duty cycle for drive #4 (16 bit)

COMMAND_CALIBRATE_PWM1 = 13 # Set the PWM duty cycle for drive #1 (16 bit, ignores limit checks)

COMMAND_CALIBRATE_PWM2 = 14 # Set the PWM duty cycle for drive #2 (16 bit, ignores limit checks)

COMMAND_CALIBRATE_PWM3 = 15 # Set the PWM duty cycle for drive #3 (16 bit, ignores limit checks)

COMMAND_CALIBRATE_PWM4 = 16 # Set the PWM duty cycle for drive #4 (16 bit, ignores limit checks)

COMMAND_GET_PWM_MIN_1 = 17 # Get the minimum allowed PWM duty cycle for drive #1

COMMAND_GET_PWM_MAX_1 = 18 # Get the maximum allowed PWM duty cycle for drive #1

COMMAND_GET_PWM_BOOT_1 = 19 # Get the startup PWM duty cycle for drive #1

COMMAND_GET_PWM_MIN_2 = 20 # Get the minimum allowed PWM duty cycle for drive #2

COMMAND_GET_PWM_MAX_2 = 21 # Get the maximum allowed PWM duty cycle for drive #2

COMMAND_GET_PWM_BOOT_2 = 22 # Get the startup PWM duty cycle for drive #2

COMMAND_GET_PWM_MIN_3 = 23 # Get the minimum allowed PWM duty cycle for drive #3

COMMAND_GET_PWM_MAX_3 = 24 # Get the maximum allowed PWM duty cycle for drive #3

COMMAND_GET_PWM_BOOT_3 = 25 # Get the startup PWM duty cycle for drive #3

COMMAND_GET_PWM_MIN_4 = 26 # Get the minimum allowed PWM duty cycle for drive #4

COMMAND_GET_PWM_MAX_4 = 27 # Get the maximum allowed PWM duty cycle for drive #4

COMMAND_GET_PWM_BOOT_4 = 28 # Get the startup PWM duty cycle for drive #4

COMMAND_SET_PWM_MIN_1 = 29 # Set the minimum allowed PWM duty cycle for drive #1

COMMAND_SET_PWM_MAX_1 = 30 # Set the maximum allowed PWM duty cycle for drive #1

COMMAND_SET_PWM_BOOT_1 = 31 # Set the startup PWM duty cycle for drive #1

COMMAND_SET_PWM_MIN_2 = 32 # Set the minimum allowed PWM duty cycle for drive #2

COMMAND_SET_PWM_MAX_2 = 33 # Set the maximum allowed PWM duty cycle for drive #2

COMMAND_SET_PWM_BOOT_2 = 34 # Set the startup PWM duty cycle for drive #2

COMMAND_SET_PWM_MIN_3 = 35 # Set the minimum allowed PWM duty cycle for drive #3

COMMAND_SET_PWM_MAX_3 = 36 # Set the maximum allowed PWM duty cycle for drive #3

COMMAND_SET_PWM_BOOT_3 = 37 # Set the startup PWM duty cycle for drive #3

COMMAND_SET_PWM_MIN_4 = 38 # Set the minimum allowed PWM duty cycle for drive #4

COMMAND_SET_PWM_MAX_4 = 39 # Set the maximum allowed PWM duty cycle for drive #4

COMMAND_SET_PWM_BOOT_4 = 40 # Set the startup PWM duty cycle for drive #4

COMMAND_GET_FILTER_USM1 = 41 # Get the filtered time measured by ultrasonic #1 in us (0 for no detection)

COMMAND_GET_FILTER_USM2 = 42 # Get the filtered time measured by ultrasonic #2 in us (0 for no detection)

COMMAND_GET_FILTER_USM3 = 43 # Get the filtered time measured by ultrasonic #3 in us (0 for no detection)

COMMAND_GET_FILTER_USM4 = 44 # Get the filtered time measured by ultrasonic #4 in us (0 for no detection)

COMMAND_GET_ID = 0x99 # Get the board identifier

COMMAND_SET_I2C_ADD = 0xAA # Set a new I2C address

COMMAND_VALUE_FWD = 1 # I2C value representing forward

COMMAND_VALUE_REV = 2 # I2C value representing reverse

COMMAND_VALUE_ON = 1 # I2C value representing on

COMMAND_VALUE_OFF = 0 # I2C value representing off

def ScanForUltraBorg(busNumber = 1):

"""

ScanForUltraBorg([busNumber])

Scans the I²C bus for a UltraBorg boards and returns a list of all usable addresses

The busNumber if supplied is which I²C bus to scan, 0 for Rev 1 boards, 1 for Rev 2 boards, if not supplied the default is 1

"""

found = []

print 'Scanning I²C bus #%d' % (busNumber)

bus = smbus.SMBus(busNumber)

for address in range(0x03, 0x78, 1):

try:

i2cRecv = bus.read_i2c_block_data(address, COMMAND_GET_ID, I2C_MAX_LEN)

if len(i2cRecv) == I2C_MAX_LEN:

if i2cRecv[1] == I2C_ID_SERVO_USM:

print 'Found UltraBorg at %02X' % (address)

found.append(address)

else:

pass

else:

pass

except KeyboardInterrupt:

raise

except:

pass

if len(found) == 0:

print 'No UltraBorg boards found, is bus #%d correct (should be 0 for Rev 1, 1 for Rev 2)' % (busNumber)

elif len(found) == 1:

print '1 UltraBorg board found'

else:

print '%d UltraBorg boards found' % (len(found))

return found

def SetNewAddress(newAddress, oldAddress = -1, busNumber = 1):

"""

SetNewAddress(newAddress, [oldAddress], [busNumber])

Scans the I²C bus for the first UltraBorg and sets it to a new I2C address

If oldAddress is supplied it will change the address of the board at that address rather than scanning the bus

The busNumber if supplied is which I²C bus to scan, 0 for Rev 1 boards, 1 for Rev 2 boards, if not supplied the default is 1

Warning, this new I²C address will still be used after resetting the power on the device

"""

if newAddress < 0x03:

print 'Error, I²C addresses below 3 (0x03) are reserved, use an address between 3 (0x03) and 119 (0x77)'

return

elif newAddress > 0x77:

print 'Error, I²C addresses above 119 (0x77) are reserved, use an address between 3 (0x03) and 119 (0x77)'

return

if oldAddress < 0x0:

found = ScanForUltraBorg(busNumber)

if len(found) < 1:

print 'No UltraBorg boards found, cannot set a new I²C address!'

return

else:

oldAddress = found[0]

print 'Changing I²C address from %02X to %02X (bus #%d)' % (oldAddress, newAddress, busNumber)

bus = smbus.SMBus(busNumber)

try:

i2cRecv = bus.read_i2c_block_data(oldAddress, COMMAND_GET_ID, I2C_MAX_LEN)

if len(i2cRecv) == I2C_MAX_LEN:

if i2cRecv[1] == I2C_ID_SERVO_USM:

foundChip = True

print 'Found UltraBorg at %02X' % (oldAddress)

else:

foundChip = False

print 'Found a device at %02X, but it is not a UltraBorg (ID %02X instead of %02X)' % (oldAddress, i2cRecv[1], I2C_ID_SERVO_USM)

else:

foundChip = False

print 'Missing UltraBorg at %02X' % (oldAddress)

except KeyboardInterrupt:

raise

except:

foundChip = False

print 'Missing UltraBorg at %02X' % (oldAddress)

if foundChip:

bus.write_byte_data(oldAddress, COMMAND_SET_I2C_ADD, newAddress)

time.sleep(0.1)

print 'Address changed to %02X, attempting to talk with the new address' % (newAddress)

try:

i2cRecv = bus.read_i2c_block_data(newAddress, COMMAND_GET_ID, I2C_MAX_LEN)

if len(i2cRecv) == I2C_MAX_LEN:

if i2cRecv[1] == I2C_ID_SERVO_USM:

foundChip = True

print 'Found UltraBorg at %02X' % (newAddress)

else:

foundChip = False

print 'Found a device at %02X, but it is not a UltraBorg (ID %02X instead of %02X)' % (newAddress, i2cRecv[1], I2C_ID_SERVO_USM)

else:

foundChip = False

print 'Missing UltraBorg at %02X' % (newAddress)

except KeyboardInterrupt:

raise

except:

foundChip = False

print 'Missing UltraBorg at %02X' % (newAddress)

if foundChip:

print 'New I²C address of %02X set successfully' % (newAddress)

else:

print 'Failed to set new I²C address...'

# Class used to control UltraBorg

class UltraBorg:

"""

This module is designed to communicate with the UltraBorg

busNumber I²C bus on which the UltraBorg is attached (Rev 1 is bus 0, Rev 2 is bus 1)

bus the smbus object used to talk to the I²C bus

i2cAddress The I²C address of the UltraBorg chip to control

foundChip True if the UltraBorg chip can be seen, False otherwise

printFunction Function reference to call when printing text, if None "print" is used

"""

# Shared values used by this class

busNumber = 1 # Check here for Rev 1 vs Rev 2 and select the correct bus

i2cAddress = I2C_ID_SERVO_USM # I²C address, override for a different address

bus = None

foundChip = False

printFunction = None

# Default calibration adjustments to standard values

PWM_MIN_1 = PWM_MIN

PWM_MAX_1 = PWM_MAX

PWM_MIN_2 = PWM_MIN

PWM_MAX_2 = PWM_MAX

PWM_MIN_3 = PWM_MIN

PWM_MAX_3 = PWM_MAX

PWM_MIN_4 = PWM_MIN

PWM_MAX_4 = PWM_MAX

def Print(self, message):

"""

Print(message)

Wrapper used by the UltraBorg instance to print messages, will call printFunction if set, print otherwise

"""

if self.printFunction == None:

print message

else:

self.printFunction(message)

def NoPrint(self, message):

"""

NoPrint(message)

Does nothing, intended for disabling diagnostic printout by using:

UB = UltraBorg.UltraBorg()

UB.printFunction = UB.NoPrint

"""

pass

def Init(self, tryOtherBus = True):

"""

Init([tryOtherBus])

Prepare the I2C driver for talking to the UltraBorg

If tryOtherBus is True or omitted, this function will attempt to use the other bus if the UltraBorg devices can not be found on the current busNumber

"""

self.Print('Loading UltraBorg on bus %d, address %02X' % (self.busNumber, self.i2cAddress))

# Open the bus

self.bus = smbus.SMBus(self.busNumber)

# Check for UltraBorg

try:

i2cRecv = self.bus.read_i2c_block_data(self.i2cAddress, COMMAND_GET_ID, I2C_MAX_LEN)

if len(i2cRecv) == I2C_MAX_LEN:

if i2cRecv[1] == I2C_ID_SERVO_USM:

self.foundChip = True

self.Print('Found UltraBorg at %02X' % (self.i2cAddress))

else:

self.foundChip = False

self.Print('Found a device at %02X, but it is not a UltraBorg (ID %02X instead of %02X)' % (self.i2cAddress, i2cRecv[1], I2C_ID_SERVO_USM))

else:

self.foundChip = False

self.Print('Missing UltraBorg at %02X' % (self.i2cAddress))

except KeyboardInterrupt:

raise

except:

self.foundChip = False

self.Print('Missing UltraBorg at %02X' % (self.i2cAddress))

# See if we are missing chips

if not self.foundChip:

self.Print('UltraBorg was not found')

if tryOtherBus:

if self.busNumber == 1:

self.busNumber = 0

else:

self.busNumber = 1

self.Print('Trying bus %d instead' % (self.busNumber))

self.Init(False)

else:

self.Print('Are you sure your UltraBorg is properly attached, the correct address is used, and the I2C drivers are running?')

self.bus = None

else:

self.Print('UltraBorg loaded on bus %d' % (self.busNumber))

# Read the calibration settings from the UltraBorg

self.PWM_MIN_1 = self.GetWithRetry(self.GetServoMinimum1, 5)

self.PWM_MAX_1 = self.GetWithRetry(self.GetServoMaximum1, 5)

self.PWM_MIN_2 = self.GetWithRetry(self.GetServoMinimum2, 5)

self.PWM_MAX_2 = self.GetWithRetry(self.GetServoMaximum2, 5)

self.PWM_MIN_3 = self.GetWithRetry(self.GetServoMinimum3, 5)

self.PWM_MAX_3 = self.GetWithRetry(self.GetServoMaximum3, 5)

self.PWM_MIN_4 = self.GetWithRetry(self.GetServoMinimum4, 5)

self.PWM_MAX_4 = self.GetWithRetry(self.GetServoMaximum4, 5)

def GetWithRetry(self, function, count):

"""

value = GetWithRetry(function, count)

Attempts to read a value multiple times before giving up

Pass a get function with no parameters

e.g.

distance = GetWithRetry(UB.GetDistance1, 5)

Will try UB.GetDistance1() upto 5 times, returning when it gets a value

Useful for ensuring a read is successful

"""

value = None

for i in range(count):

okay = True

try:

value = function()

except KeyboardInterrupt:

raise

except:

okay = False

if okay:

break

return value

def SetWithRetry(self, setFunction, getFunction, value, count):

"""

worked = SetWithRetry(setFunction, getFunction, value, count)

Attempts to write a value multiple times before giving up

Pass a set function with one parameter, and a get function no parameters

The get function will be used to check if the set worked, if not it will be repeated

e.g.

worked = SetWithRetry(UB.SetServoMinimum1, UB.GetServoMinimum1, 2000, 5)

Will try UB.SetServoMinimum1(2000) upto 5 times, returning when UB.GetServoMinimum1 returns 2000.

Useful for ensuring a write is successful

"""

for i in range(count):

okay = True

try:

setFunction(value)

readValue = getFunction()

except KeyboardInterrupt:

raise

except:

okay = False

if okay:

if readValue == value:

break

else:

okay = False

return okay

def ReadWithCheck(self, address, command, length):

"""

i2cRecv = ReadWithCheck(address, command, length)

Attempts an I2C read, checks if the bus tried to read too fast and re-tries

Only intended for internal usage

"""

unfinished = True

while unfinished:

i2cRecv = self.bus.read_i2c_block_data(address, command, length)

if len(i2cRecv) > 0:

if i2cRecv[0] == READ_TOO_FAST:

self.Print('I2C read was too fast, retrying')

else:

unfinished = False

else:

self.Print('Empty I2C reply, retrying...')

return i2cRecv

def GetDistance1(self):

"""

distance = GetDistance1()

Gets the filtered distance for ultrasonic module #1 in millimeters

Returns 0 for no object detected or no ultrasonic module attached

If you need a faster response try GetRawDistance1 instead (no filtering)

e.g.

0 -> No object in range

25 -> Object 25 mm away

1000 -> Object 1000 mm (1 m) away

3500 -> Object 3500 mm (3.5 m) away

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_FILTER_USM1, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading ultrasonic #1 distance!')

return

time_us = (i2cRecv[1] << 8) + i2cRecv[2]

if time_us == 65535:

time_us = 0

return time_us * USM_US_TO_MM

def GetDistance2(self):

"""

distance = GetDistance2()

Gets the filtered distance for ultrasonic module #2 in millimeters

Returns 0 for no object detected or no ultrasonic module attached

If you need a faster response try GetRawDistance2 instead (no filtering)

e.g.

0 -> No object in range

25 -> Object 25 mm away

1000 -> Object 1000 mm (1 m) away

3500 -> Object 3500 mm (3.5 m) away

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_FILTER_USM2, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading ultrasonic #2 distance!')

return

time_us = (i2cRecv[1] << 8) + i2cRecv[2]

if time_us == 65535:

time_us = 0

return time_us * USM_US_TO_MM

def GetDistance3(self):

"""

distance = GetDistance3()

Gets the filtered distance for ultrasonic module #3 in millimeters

Returns 0 for no object detected or no ultrasonic module attached

If you need a faster response try GetRawDistance3 instead (no filtering)

e.g.

0 -> No object in range

25 -> Object 25 mm away

1000 -> Object 1000 mm (1 m) away

3500 -> Object 3500 mm (3.5 m) away

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_FILTER_USM3, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading ultrasonic #3 distance!')

return

time_us = (i2cRecv[1] << 8) + i2cRecv[2]

if time_us == 65535:

time_us = 0

return time_us * USM_US_TO_MM

def GetDistance4(self):

"""

distance = GetDistance4()

Gets the filtered distance for ultrasonic module #4 in millimeters

Returns 0 for no object detected or no ultrasonic module attached

If you need a faster response try GetRawDistance4 instead (no filtering)

e.g.

0 -> No object in range

25 -> Object 25 mm away

1000 -> Object 1000 mm (1 m) away

3500 -> Object 3500 mm (3.5 m) away

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_FILTER_USM4, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading ultrasonic #4 distance!')

return

time_us = (i2cRecv[1] << 8) + i2cRecv[2]

if time_us == 65535:

time_us = 0

return time_us * USM_US_TO_MM

def GetRawDistance1(self):

"""

distance = GetRawDistance1()

Gets the raw distance for ultrasonic module #1 in millimeters

Returns 0 for no object detected or no ultrasonic module attached

For a filtered (less jumpy) reading use GetDistance1

e.g.

0 -> No object in range

25 -> Object 25 mm away

1000 -> Object 1000 mm (1 m) away

3500 -> Object 3500 mm (3.5 m) away

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_TIME_USM1, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading ultrasonic #1 distance!')

return

time_us = (i2cRecv[1] << 8) + i2cRecv[2]

if time_us == 65535:

time_us = 0

return time_us * USM_US_TO_MM

def GetRawDistance2(self):

"""

distance = GetRawDistance2()

Gets the raw distance for ultrasonic module #2 in millimeters

Returns 0 for no object detected or no ultrasonic module attached

For a filtered (less jumpy) reading use GetDistance2

e.g.

0 -> No object in range

25 -> Object 25 mm away

1000 -> Object 1000 mm (1 m) away

3500 -> Object 3500 mm (3.5 m) away

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_TIME_USM2, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading ultrasonic #2 distance!')

return

time_us = (i2cRecv[1] << 8) + i2cRecv[2]

if time_us == 65535:

time_us = 0

return time_us * USM_US_TO_MM

def GetRawDistance3(self):

"""

distance = GetRawDistance3()

Gets the raw distance for ultrasonic module #3 in millimeters

Returns 0 for no object detected or no ultrasonic module attached

For a filtered (less jumpy) reading use GetDistance3

e.g.

0 -> No object in range

25 -> Object 25 mm away

1000 -> Object 1000 mm (1 m) away

3500 -> Object 3500 mm (3.5 m) away

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_TIME_USM3, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading ultrasonic #3 distance!')

return

time_us = (i2cRecv[1] << 8) + i2cRecv[2]

if time_us == 65535:

time_us = 0

return time_us * USM_US_TO_MM

def GetRawDistance4(self):

"""

distance = GetRawDistance4()

Gets the distance for ultrasonic module #4 in millimeters

Returns 0 for no object detected or no ultrasonic module attached

For a filtered (less jumpy) reading use GetDistance4

e.g.

0 -> No object in range

25 -> Object 25 mm away

1000 -> Object 1000 mm (1 m) away

3500 -> Object 3500 mm (3.5 m) away

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_TIME_USM4, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading ultrasonic #4 distance!')

return

time_us = (i2cRecv[1] << 8) + i2cRecv[2]

if time_us == 65535:

time_us = 0

return time_us * USM_US_TO_MM

def GetServoPosition1(self):

"""

position = GetServoPosition1()

Gets the drive position for servo output #1

0 is central, -1 is maximum left, +1 is maximum right

e.g.

0 -> Central

0.5 -> 50% to the right

1 -> 100% to the right

-0.75 -> 75% to the left

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_PWM1, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading servo output #1!')

return

pwmDuty = (i2cRecv[1] << 8) + i2cRecv[2]

powerOut = (float(pwmDuty) - self.PWM_MIN_1) / (self.PWM_MAX_1 - self.PWM_MIN_1)

return (2.0 * powerOut) - 1.0

def GetServoPosition2(self):

"""

position = GetServoPosition2()

Gets the drive position for servo output #2

0 is central, -1 is maximum left, +1 is maximum right

e.g.

0 -> Central

0.5 -> 50% to the right

1 -> 100% to the right

-0.75 -> 75% to the left

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_PWM2, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading servo output #2!')

return

pwmDuty = (i2cRecv[1] << 8) + i2cRecv[2]

powerOut = (float(pwmDuty) - self.PWM_MIN_2) / (self.PWM_MAX_2 - self.PWM_MIN_2)

return (2.0 * powerOut) - 1.0

def GetServoPosition3(self):

"""

position = GetServoPosition3()

Gets the drive position for servo output #3

0 is central, -1 is maximum left, +1 is maximum right

e.g.

0 -> Central

0.5 -> 50% to the right

1 -> 100% to the right

-0.75 -> 75% to the left

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_PWM3, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading servo output #3!')

return

pwmDuty = (i2cRecv[1] << 8) + i2cRecv[2]

powerOut = (float(pwmDuty) - self.PWM_MIN_3) / (self.PWM_MAX_3 - self.PWM_MIN_3)

return (2.0 * powerOut) - 1.0

def GetServoPosition4(self):

"""

position = GetServoPosition4()

Gets the drive position for servo output #4

0 is central, -1 is maximum left, +1 is maximum right

e.g.

0 -> Central

0.5 -> 50% to the right

1 -> 100% to the right

-0.75 -> 75% to the left

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_PWM4, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading servo output #4!')

return

pwmDuty = (i2cRecv[1] << 8) + i2cRecv[2]

powerOut = (float(pwmDuty) - self.PWM_MIN_4) / (self.PWM_MAX_4 - self.PWM_MIN_4)

return (2.0 * powerOut) - 1.0

def SetServoPosition1(self, position):

"""

SetServoPosition1(position)

Sets the drive position for servo output #1

0 is central, -1 is maximum left, +1 is maximum right

e.g.

0 -> Central

0.5 -> 50% to the right

1 -> 100% to the right

-0.75 -> 75% to the left

"""

powerOut = (position + 1.0) / 2.0

pwmDuty = int((powerOut * (self.PWM_MAX_1 - self.PWM_MIN_1)) + self.PWM_MIN_1)

pwmDutyLow = pwmDuty & 0xFF

pwmDutyHigh = (pwmDuty >> 8) & 0xFF

try:

self.bus.write_i2c_block_data(self.i2cAddress, COMMAND_SET_PWM1, [pwmDutyHigh, pwmDutyLow])

except KeyboardInterrupt:

raise

except:

self.Print('Failed sending servo output #1!')

def SetServoPosition2(self, position):

"""

SetServoPosition2(position)

Sets the drive position for servo output #2

0 is central, -1 is maximum left, +1 is maximum right

e.g.

0 -> Central

0.5 -> 50% to the right

1 -> 100% to the right

-0.75 -> 75% to the left

"""

powerOut = (position + 1.0) / 2.0

pwmDuty = int((powerOut * (self.PWM_MAX_2 - self.PWM_MIN_2)) + self.PWM_MIN_2)

pwmDutyLow = pwmDuty & 0xFF

pwmDutyHigh = (pwmDuty >> 8) & 0xFF

try:

self.bus.write_i2c_block_data(self.i2cAddress, COMMAND_SET_PWM2, [pwmDutyHigh, pwmDutyLow])

except KeyboardInterrupt:

raise

except:

self.Print('Failed sending servo output #2!')

def SetServoPosition3(self, position):

"""

SetServoPosition3(position)

Sets the drive position for servo output #3

0 is central, -1 is maximum left, +1 is maximum right

e.g.

0 -> Central

0.5 -> 50% to the right

1 -> 100% to the right

-0.75 -> 75% to the left

"""

powerOut = (position + 1.0) / 2.0

pwmDuty = int((powerOut * (self.PWM_MAX_3 - self.PWM_MIN_3)) + self.PWM_MIN_3)

pwmDutyLow = pwmDuty & 0xFF

pwmDutyHigh = (pwmDuty >> 8) & 0xFF

try:

self.bus.write_i2c_block_data(self.i2cAddress, COMMAND_SET_PWM3, [pwmDutyHigh, pwmDutyLow])

except KeyboardInterrupt:

raise

except:

self.Print('Failed sending servo output #3!')

def SetServoPosition4(self, position):

"""

SetServoPosition4(position)

Sets the drive position for servo output #4

0 is central, -1 is maximum left, +1 is maximum right

e.g.

0 -> Central

0.5 -> 50% to the right

1 -> 100% to the right

-0.75 -> 75% to the left

"""

powerOut = (position + 1.0) / 2.0

pwmDuty = int((powerOut * (self.PWM_MAX_4 - self.PWM_MIN_4)) + self.PWM_MIN_4)

pwmDutyLow = pwmDuty & 0xFF

pwmDutyHigh = (pwmDuty >> 8) & 0xFF

try:

self.bus.write_i2c_block_data(self.i2cAddress, COMMAND_SET_PWM4, [pwmDutyHigh, pwmDutyLow])

except KeyboardInterrupt:

raise

except:

self.Print('Failed sending servo output #1!')

def GetServoMinimum1(self):

"""

pwmLevel = GetServoMinimum1()

Gets the minimum PWM level for servo output #1

This corresponds to position -1

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 -> 1 ms servo burst, typical shortest burst

4000 -> 2 ms servo burst, typical longest burst

3000 -> 1.5 ms servo burst, typical centre

5000 -> 2.5 ms servo burst, higher than typical longest burst

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_PWM_MIN_1, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading servo #1 minimum burst!')

return

return (i2cRecv[1] << 8) + i2cRecv[2]

def GetServoMinimum2(self):

"""

pwmLevel = GetServoMinimum2()

Gets the minimum PWM level for servo output #2

This corresponds to position -1

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 -> 1 ms servo burst, typical shortest burst

4000 -> 2 ms servo burst, typical longest burst

3000 -> 1.5 ms servo burst, typical centre

5000 -> 2.5 ms servo burst, higher than typical longest burst

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_PWM_MIN_2, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading servo #2 minimum burst!')

return

return (i2cRecv[1] << 8) + i2cRecv[2]

def GetServoMinimum3(self):

"""

pwmLevel = GetServoMinimum3()

Gets the minimum PWM level for servo output #3

This corresponds to position -1

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 -> 1 ms servo burst, typical shortest burst

4000 -> 2 ms servo burst, typical longest burst

3000 -> 1.5 ms servo burst, typical centre

5000 -> 2.5 ms servo burst, higher than typical longest burst

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_PWM_MIN_3, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading servo #3 minimum burst!')

return

return (i2cRecv[1] << 8) + i2cRecv[2]

def GetServoMinimum4(self):

"""

pwmLevel = GetServoMinimum4()

Gets the minimum PWM level for servo output #4

This corresponds to position -1

The value is an integer where 2000 represents a 1 ms servo burst

e.g.

2000 -> 1 ms servo burst, typical shortest burst

4000 -> 2 ms servo burst, typical longest burst

3000 -> 1.5 ms servo burst, typical centre

5000 -> 2.5 ms servo burst, higher than typical longest burst

"""

try:

i2cRecv = self.ReadWithCheck(self.i2cAddress, COMMAND_GET_PWM_MIN_4, I2C_MAX_LEN)

except KeyboardInterrupt:

raise

except:

self.Print('Failed reading servo #4 minimum burst!')

return

return (i2cRecv[1] << 8) + i2cRecv[2]

def GetServoMaximum1(self):

"""